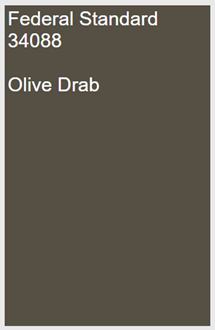

Olive Drab Zinc Plating

Field-tested and approved for military mission-critical hardware

To withstand combat conditions and function dependably in the field, firearms, munitions, and aerospace components must be finished with processes and coatings that protect them from corrosion and premature wear. That’s why leading manufacturers in the defense, military, aerospace, and firearms industries rely on Greystone Defense Finishing to electroplate their high-volume, mission-critical ferrous metal parts with Olive Drab zinc plating.

Our Olive Drab chromate provides superior corrosion and wear resistance and leaves parts with a matte finish that meets MIL-SPEC standards. It is an excellent alternative to Olive Drab cadmium and paints.

Why Plate Parts with Olive Drab Zinc?

Zinc plating deposits a sacrificial layer of zinc—which can be customized based on your needs and specifications—on a metal substrate. The zinc coating protects the metal from rust and other forms of corrosion and makes the finished part more resistant to wear. As a result, components plated with zinc require less maintenance and deliver longer-lasting performance than parts not plated with zinc.

After parts are plated, they can be finished with a sealer or color chromate (including Clear, Black, Yellow and Olive Drab). Olive Drab zinc chromate coating is popular in defense applications because it maximizes the inherent benefits of zinc plating. In addition to improving the performance of metal parts, Greystone’s Olive Drab coating is non-reflective, which makes it suitable for parts that must be camouflaged or used in low-visibility environments.

Our engineers have extensive experience plating difficult geometries and can plate a diverse range of part types. All parts are electroplated on Greystone’s fully automated, high-volume production lines in Virginia and Rhode Island, which are equipped to handle both rack and barrel operations.

Hexavalent vs. Trivalent Chromate

While trivalent chromates are more widely used and environmentally friendly, they often result in a lighter, less pronounced color and offer a lesser degree of resistance to wear and corrosion than hexavalent chromates. Hexavalent chromates, by contrast, produce a deeper and more defined Olive Drab appearance, which is preferred in military and defense applications. For trivalent chromates to achieve the same performance and match the color of hexavalent chromates, additional dyes and topcoats may need to be used, increasing cost. For these reasons, hexavalent Olive Drab chromate remains the coating of choice for the defense and firearms industries.

The Advantages of Hexavalent Olive Drab Zinc Plating

Greystone Defense Finishing’s Olive Drab chromate offers:

- Superlative Corrosion Resistance: Our Olive Drab chromate performs exceptionally well in harsh environments and in most cases exceeds 500 hours to red rust in salt spray tests

- Superior Durability & Wear Resistance: Olive Drab does not flake, chip or crack, despite repeated and heavy wear and protects the metal substrate below

- Self-Healing Abilities: Hexavalent chromates contain compounds that provide unique “self-healing” characteristics; when scratched, the coating can re-passivate itself, leading to enhanced corrosion resistance and long-lasting appearance

- Matte Finish: Our Olive Drab chromate is matte and meets military standards and aesthetic requirements

Specifications

Zinc-plated parts finished with Greystone’s Olive Drab chromate meet the following specifications and are compatible with RoHS exemptions for military applications where Cr6+ is permitted:

- ASTM B633 (Type II and Type VI)

- MIL-STD 171

- QQ-Z-325

Get a Quote Today

Manufacturers in the defense, military, aerospace and firearms industries rely on Greystone Defense Finishing to electroplate their parts with Olive Drab zinc. We serve Tier 1 defense suppliers and hold the following certifications:

- MIL-DTL-5541/MIL-STD-171

- ITAR (registrant code M23917)

- Nadcap AC7004

- Nadcap AC7108/4

- IATF 16949

- ISO 9001

- ISO 13485

- ISO 14001

Speak with one of our precision, high-volume zinc plating experts to learn more or get a quote.